wet compression test video|cylinder engine compression test chart : warehouse A detailed video on how to do a wet compression test and a dry compression test. We also cover leak down testing and engine diagnostics. WEB3. 4. 5. 6. Assista vídeos pornô de Gostosa Tatuada de graça, aqui no Pornhub.com. Descubra a crescente coleção de vídeos e filmes Mais relevantes explícitos em alta .

{plog:ftitle_list}

20 de dez. de 2020 · Transmissão ao vivo de Totolec Show Oficial 20/12/20.

Check out the video on compression testing first. If you have a low (not 0) cylinder, a wet compression test is a common next step. Brian Eslick from How to Automotive http://www.howtoautomotive.com takes you step-by-step through the process of preforming a wet and dry compression test . A detailed video on how to do a wet compression test and a dry compression test. We also cover leak down testing and engine diagnostics.Wet Compression Test. Cylinder compression tests identify combustion engine cylinders with poor compression. If a cylinder has low compression, perform a wet compression test to indicate whether a bad valve, head gasket, or worn .

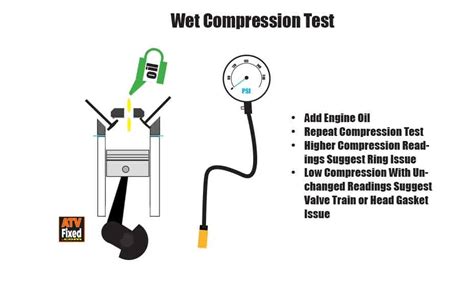

Perform a wet compression test if a cylinder's pressure is below specifications. This test indicates whether the valves, head gasket, or the piston rings are at fault. Inject a small amount of oil, usually about a tablespoon, into the cylinder .

A cylinder leak down test, is similar to a compression test. Because, it tells you how well your engine’s cylinders are sealing. And, instead of measuring pressure, it measures pressure loss. After you have done a basic . Compression testing measures the condition of an engine's cylinders, rings, and valves. This article covers both Dry and Wet compression tests.

перенастройка влагомера wile 55 своими руками

The PSI typically rises when you do a wet test instead of a dry one. The change can help you determine what is wrong with the cylinder. If the test worked, a large change could mean the piston rings have worn out.

Everything you need to know: How TO Check Your Engine Compression. Dry and Wet Tests. Simple to follow, we tried clearly explain how to perform the engine co. How To Do A Compression Test (Wet) Many automotive books describe, a dry and a wet compression test together. Usually these tests, must be viewed together to isolate . A detailed video on how to do a wet compression test and a dry compression test. We also cover leak down testing and engine diagnostics. SUBSCRIBE for more a.

Brian Eslick from How to Automotive http://www.howtoautomotive.com takes you step-by-step through the process of preforming a wet and dry compression test .

This step is called a wet compression test. To perform a wet compression test on a low-reading cylinder, pour one tablespoon of engine oil through the spark plug hole and into the cylinder. After cranking the engine two revolutions to . The TurboTime Podcast Videos casts. News Conferences. Resources. White Papers Useful . Wet compression systems typically have water flow rates from 0.5% to 2.5% of the gas turbine inlet-air mass flow rate—about 20 to 90 gpm for a 7EA turbine, or as much as 156 gpm of a large F-class. . Taking into consideration the water consumption . The equivalent compression reading for a cylinder that should be 135 PSI by the data at 5000′ would be 135 x .8617 = 116.33. Wet Compression Test. Many automotive books describe a dry and a wet compression test. Usually, these tests must be interpreted together to isolate the trouble in cylinders or valves. Metal in Motion shows you how to do a wet and dry compression test on small engines or powersports. Keep in mind that the compression release mechanism on mo.

Familiarize Yourself with the Engine: Before starting the compression test, it is essential to have a good understanding of the engine’s layout and components.This knowledge will help you locate the necessary and access points for the test. Ensure Proper Ventilation: Compression testing involves running the engine, which produces exhaust gases.To prevent . Crank the Engine: Have an assistant crank the engine by turning the key in the ignition while you observe the gauge.Allow the engine to crank for about 5-10 seconds or until the gauge needle stabilizes at its highest reading. Record the Reading: Note the peak pressure reading on the gauge and record it on paper.; Repeat for All Cylinders: Repeat the process for .

Worn valves, valve seats and valve train normally cause uneven compression. If only one cylinder has low compression, a burned exhaust valve, broken valve spring or broken piston rings are indicated. Dry/Wet Compression Testing – The classic wet/dry compression test is intended to detect worn piston rings by comparing cranking compression . The dry/wet compression test came about because it requires only one inexpensive gauge and most shadetrees can do it. The leakdown test requires a more expensive gauge set and an air compressor. Back in the day, before cheap-china, not one in ten average-guy-home-garages had an air compressor. Testing the engine compression on your Chevrolet or GMC 4.8L, 5.0L, or 6.0L engine is not hard to do. A compression test will help you to determine the health of your engine by measuring the pressure of the air that gets compressed by the . Parts:Compression testerhttp://amzn.to/2AQgEcSIn this video, I show the process of how to do a wet compression test on a 1992 Jeep Wrangler YJ 4.0L. Please .

Wet test for each cylinder immediately after 2), and having poured about 2tsp of engine oil into the spark plug hole before doing the test. For each test, the pressure meter was attached to the spark plug hole, all spark plugs removed, intake manifold removed (necessary to get to the spark plugs), and engine cranked 7+ times or until the needle . This tutorial will teach you everything you need to know to do a compression test on any engine. I cover the process from start to finish including what comp. If the compression is low in a cylinder, it's time to find out why. Use the leak down test to know if you should be changing head gaskets, valves, piston rin.

пермь купить влагомер

In this video we perform a dry/wet compression test. This test is a great way to see what you lose from either worn or damaged rings.

Label the paper with a heading for each cylinder and if you want to be really thorough, make two rows labeled “wet” and “dry” under each. The reading you just took can be written down under “Cylinder 1 – Dry”. . With .

Next, we will do wet compression testing and record those readings. HOW TO DO A WET COMPRESSION TEST. The test is basically the same as before. But, this time you are going to squirt about one teaspoon of 30-weight engine oil, into the spark plug hole. WARNING: Do not use more than a teaspoon of oil, or you’ll get a false high compression . Worn valves, valve seats and valve train normally cause uneven compression. If only one cylinder has low compression, a burned exhaust valve, broken valve spring or broken piston rings are indicated. Dry/Wet Compression Testing – The classic wet/dry compression test is intended to detect worn piston rings by comparing cranking compression . The compression test should show a minimum 11 - 12 bar, 160-174psi. Max difference between cylinders 0.5 bar 7 PSI Next step would be a "wet" compression test. This tests the ring seal. Pour about a teaspoon of oil into each cylinder and test the compression again. If this gives a higher compression pressure, you have a problem with the rings .

пинус елена влагомер

Wet compression is a strategy adopted to increase the power output of gas turbines, with respect to dry conditions, usually also incrementing the operating range of the compressor. However, stall and surge are two aerodynamic instabilities which depend on many factors, and they are expected to occur even in wet compression at low flow rates. Despite . Engine CompressionAtmospheric pressure at sea level is approximately 14.7 psi.A 9:1 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level (9x14.7=132.3 . A compression test is always a good way to determine if the symptoms you’re experiencing are related to internal engine damage. However, if compression is found to be low inside the engine, significant repairs or in some cases, complete engine replacement will be required. The key is to have a professional mechanic perform a compression test .

A “wet” compression test can be done after the standard test. Squirt a teaspoon (or less) of 30W motor oil into each cylinder, then check the compression again. The oil will help seal any broken piston rings temporarily — so if compression goes up after this, even 5%, you’ll know your engine is in need of a complete overhaul.

A cylinder leak down test or cylinder leakage test, is actually similar to a compression test: So, a compression test measures, how well your engine’s cylinders are sealing. But, a Cylinder Leak Down Test, takes it to the next level and measures, cylinder pressure loss. Although a compression test, won’t give you a detailed picture of your .Every video/post I've seen about how to do a wet compression test says to squirt "some amount" of oil down the spark plug hole. The most specific anyone seems to get is "about one tablespoon." That doesn't seem all that scientific to me, and I feel like the exact amount of oil to add varies based on the engine specs. A compression test measures a cylinder’s ability to hold pressure as the piston moves up and down. Mechanics use an oscilloscope and observe the stored pattern as the engine spins when performing a dynamic compression test. Regular engine misfires, reduced acceleration, and poor fuel economy are indicators that you need to conduct an engine .

wet compression test vs dry

A Seleção Ugandense de Futebol representa o Uganda nas competições de futebol da FIFA, sendo controlada pela Federação das Associações de Futebol de Uganda. Ela é filiada à FIFA, à CAF e à CECAFA. Tem como resultado mais expressivo um vice campeonato da Copa Africana de Nações em 1978. Nunca se classificou para uma Copa do Mundo.

wet compression test video|cylinder engine compression test chart